People, partnerships, and purpose across a decade of sustainable cashmere

In 2015, the Sustainable Fibre Alliance (SFA) began with a belief that meaningful change in the cashmere sector could only happen by working with people – not around them. From herding families and cooperatives to processors, manufacturers, brands, scientists and partners, the SFA has grown through relationships built on trust and shared responsibility.

Over the past ten years, this approach has shaped a global community working to improve animal welfare, environmental health, and livelihoods across the cashmere supply chain. Today, the SFA works across 17 aimags in Mongolia and 8 provinces in China, supporting more than 19,000 herder households in Mongolia and certifying nearly 37,000 farms in China since the programme began.

At the heart of this work is the Mongolian word nutag – a holistic understanding of homeplace that encompasses culture, identity, and traditional ecological knowledge, which, alongside scientific consensus, informs the SFA’s approach and conceptual framework. These values have formed the threads that continue to shape the SFA today.

What follows are ten threads – moments of connection, learning, and collaboration that together tell the story of the SFA’s first decade.

THREAD 1: Starting with Trust

From the outset, the SFA chose a path grounded in respect for people and place. Rather than imposing solutions, the organisation focused on building trust – listening to herders, learning from practitioners, and recognising that sustainability must be rooted in lived experience as much as technical expertise.

SFA CEO and Co-Founder Una Jones reflects:

“The SFA began with the belief that sustainability in cashmere must reflect the whole system – people, animals and the environment that connect them. As a Mongolian, I knew I wanted to ensure that our work was shaped by the concept of nutag – encompassing heritage, identity and the traditional ecological knowledge of pastoral communities, alongside scientific understanding. Ten years later, I am proud that our organisation continues to honour both in pursuit of a truly responsible fibre sector.”

THREAD 2: Building Standards Together

One of the SFA’s earliest defining moments was the collaborative development of its first Codes of Practice. These were shaped through consultation, dialogue, and shared problem-solving – ensuring they reflected both scientific evidence and on-the-ground realities.

Former Board Chair Charles “Chas” Hubbard recalls:

“Late 2015 was when SFA was set up, but things really got going in 2016 when we started work on a set of protocols… After much consultation with many interested parties, we were able to launch the two sets of protocols as ‘Codes of Practice’ at the first SFA Conference in Ulaanbaatar in 2017.”

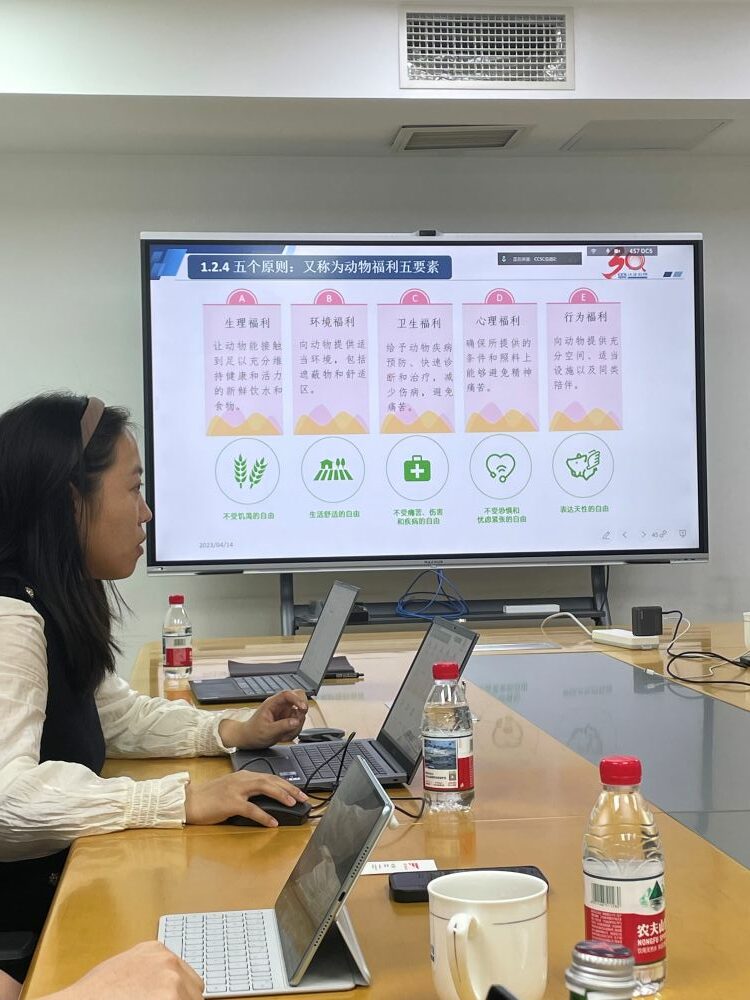

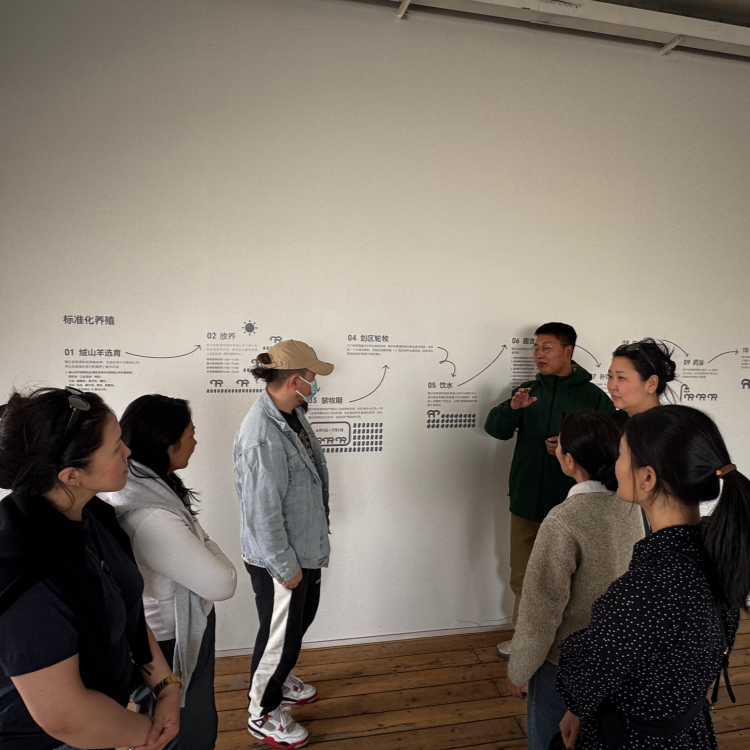

What began as two Codes of Practice for sustainable cashmere production has since grown into a comprehensive voluntary standards system. Today, the SFA stewards three full global Standards – covering Animal Fibre Production, Clean Fibre Processing, and Chain of Custody – supported by a suite of assurance, certification, oversight, and claims guidance documents. Together, these resources are designed to ensure credibility, transparency, and consistency across the cashmere supply chain and are available publicly on the SFA website.

THREAD 3: Seeing Change Through Herder Engagement

As standards moved from paper to practice, the real measure of progress became participation. Early pilots with herding organisations showed that change was strongest when communities were actively involved – shaping, adapting, and owning the process.

Chas reflects:

“While this was a significant milestone, the real work in Mongolia got underway with the engagement of Mongolian herding families and then communities to help them see the benefits to the sustainability of their market through good governance of their pastures and welfare of their animals.”

THREAD 4: Investing in the Next Generation

A deeply human moment came with the creation of the Young Herders Programme, designed to pass sustainability knowledge to future generations through education rooted in language, culture, and pastoral life.

Former Johnstons of Elgin CEO Simon Cotton recalls:

“We came to a small village school, and it was explained to us that the children of herders all lived at the school during term-time, and, in that moment, the idea behind the Young Herders Program was born. The SFA produced fantastic textbooks which rooted sustainability within Mongolian culture, trained teachers to deliver the program, and, in less than a year, we had hundreds of young herders going through training. For me, this illustrated the benefits of the SFA having its roots firmly in Mongolia, being sympathetic to herder culture and not some foreign NGO, which just flies in to do audits.”

THREAD 5: Growing with the Sector

As the SFA matured, its work expanded beyond herding to include processors, manufacturers, and brands – recognising that responsibility does not stop at the pasture gate.

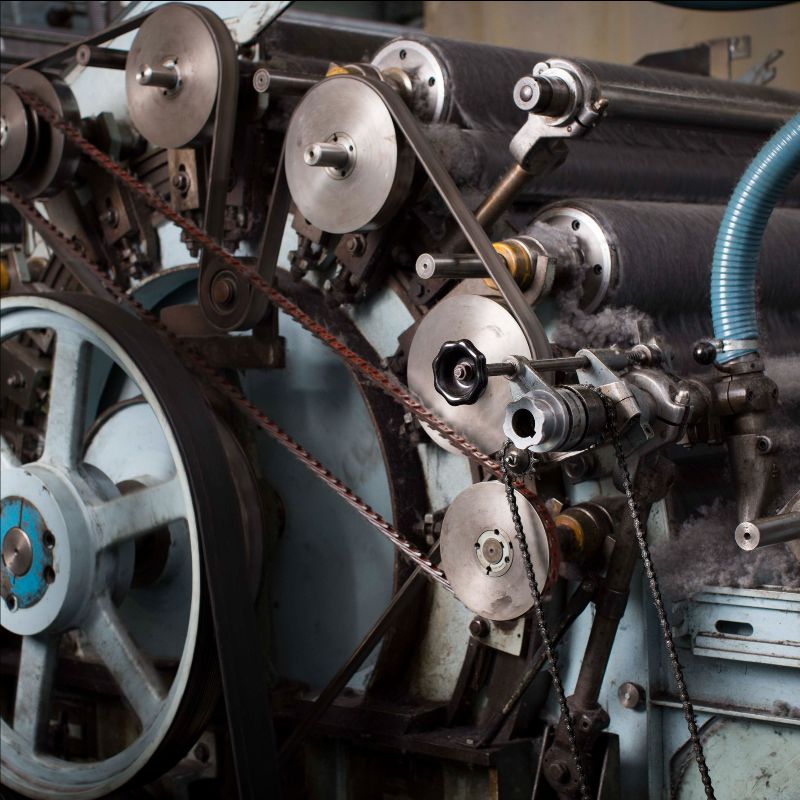

The development of the Clean Fibre Processing Code of Practice – which revolutionised the sector by eliminating harmful chemicals and embedding decent work practices – and strengthened engagement across supply chains, helped align expectations and deepen collaboration across the sector.

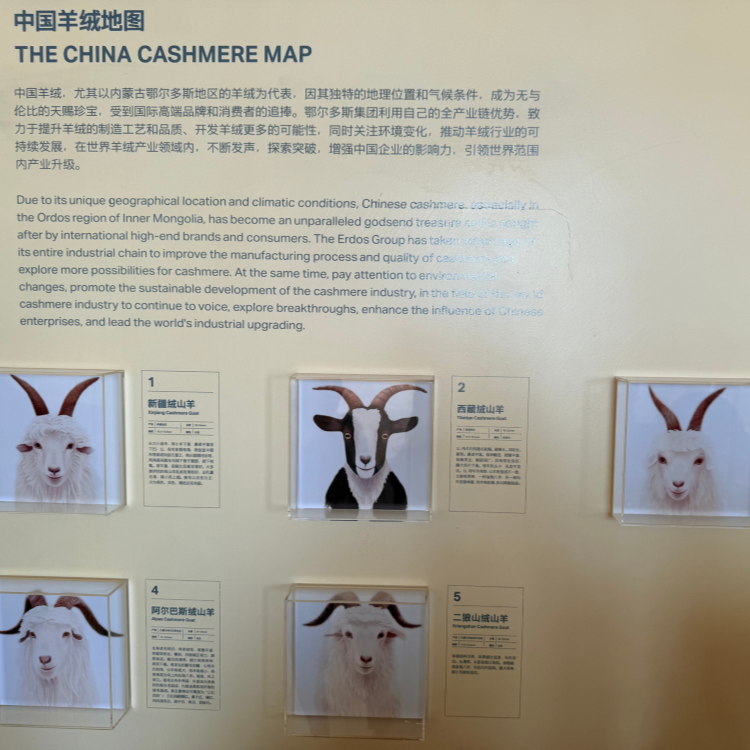

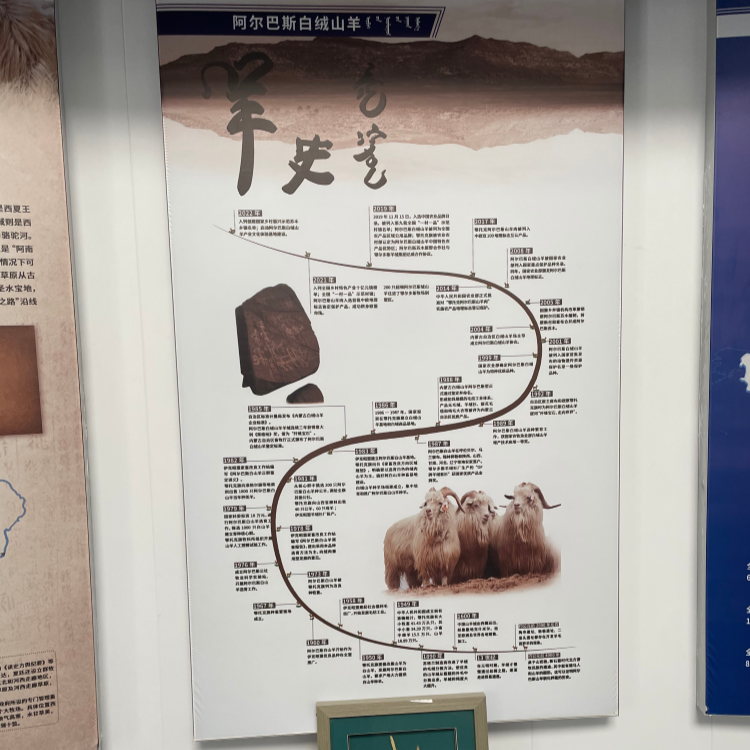

This approach guided the SFA’s expansion into China, where a partnership with the International Cooperative Committee on Animal Welfare (ICCAW) enabled the standards system to be adapted and implemented in a way that respected local contexts and industry structures. Through collaboration and dialogue, shared expectations for animal welfare, responsible production, and supply chain transparency were embedded across regions.

THREAD 6: Supporting Livelihoods Beyond Standards

The SFA’s role has never been limited to certification alone. Over time, the organisation has supported approaches that strengthen economic resilience alongside responsible practices.

Chas notes:

“We established good relations with Khan Bank of Mongolia… and we were able to negotiate, on behalf of Herders, favourable interest rates for loans if they could show that they were SFA registered.”

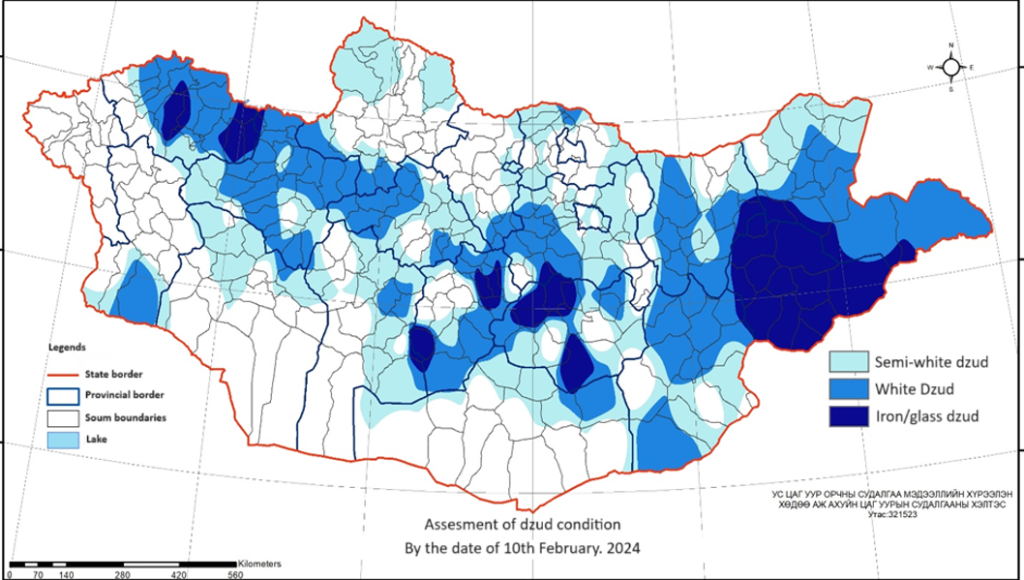

THREAD 7: Standing with Communities in Crisis

In late 2023 to early 2024, Mongolia’s severe dzud winter brought devastating losses to herding communities. Years of relationship-building meant that the SFA could respond quickly, working alongside members and partners to deliver urgent support where it was needed most.

Across two phases of response, the SFA supported 1,760 herding households across 20 cooperatives and 12 soums, helping approximately 300,000 livestock animals through the most severe period of winter.

According to Mongolia’s Ministry of Food, Agriculture & Light Industry, 11.5% of the country’s livestock – more than 7.4 million animals, including an estimated 2.5 million goats – were lost during the 2023-2024 dzud. Moments like this reflect the depth of trust that has been built over time and the importance of collective action in times of crisis.

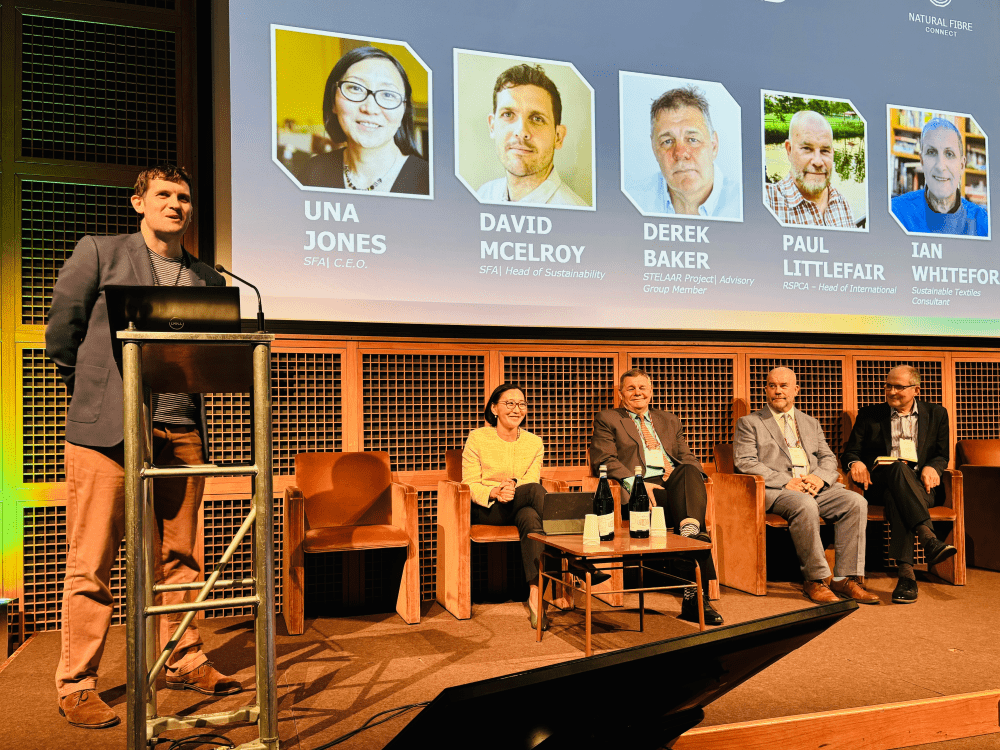

THREAD 8: Convening, Listening & Learning

Through initiatives such as the Natural Fibre Connect (NFC), the SFA has partnered with like-minded organisations in the fibre sector to create a space for dialogue across the cashmere, wool, mohair, and alpaca sectors – recognising that shared challenges require shared learning.

These moments of convening have helped build alignment, reduce fragmentation, and strengthen collaboration across the natural fibre community.

THREAD 9: From Speed to Depth

After a decade of growth, the SFA is entering a new phase – one focused on depth, consistency, and long-term stewardship of systems already built.

Current Board Chair Ian Whiteford reflects:

“As the SFA enters its next decade, we are transitioning from the rapid, entrepreneurial growth that defined our early years into a more structured, methodical phase. We have now established our presence across the major cashmere regions, and our task is no longer to move quickly into new geographies, but to deepen our influence, strengthen our systems and ensure our standards are consistently maintained. This shift from speed to depth will allow us to build the organisational clarity and long-term capability needed to support the sector effectively.”

THREAD 10: What We Carry Forward

Today, the SFA supports tens of thousands of herding households and farms across Mongolia and China, working with global brands and partners, and stewards a growing voluntary standards and traceability system – all while remaining grounded in the principle that sustainability must be lived, not imposed.

Thank you for Shaping These Threads

None of these threads exists in isolation. They are woven together through the commitment, care, and collaboration of herding families, cooperatives, processors, manufacturers, brands, members, scientists, partners, and supporters around the world.

As we reflect on ten years of the SFA, we thank everyone who has helped shape these threads – and those who will continue weaving the next chapter of sustainable cashmere.

Katy Edwards

SFA MARKETING & COMMUNICATIONS MANAGER

19 December 2025